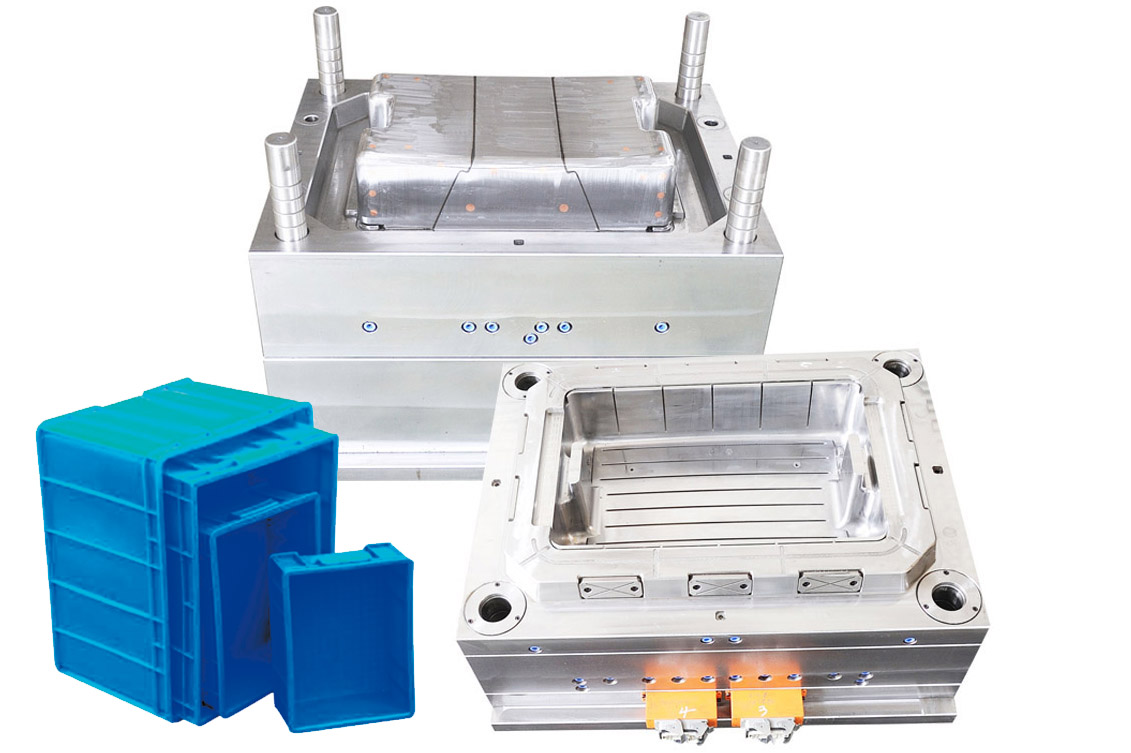

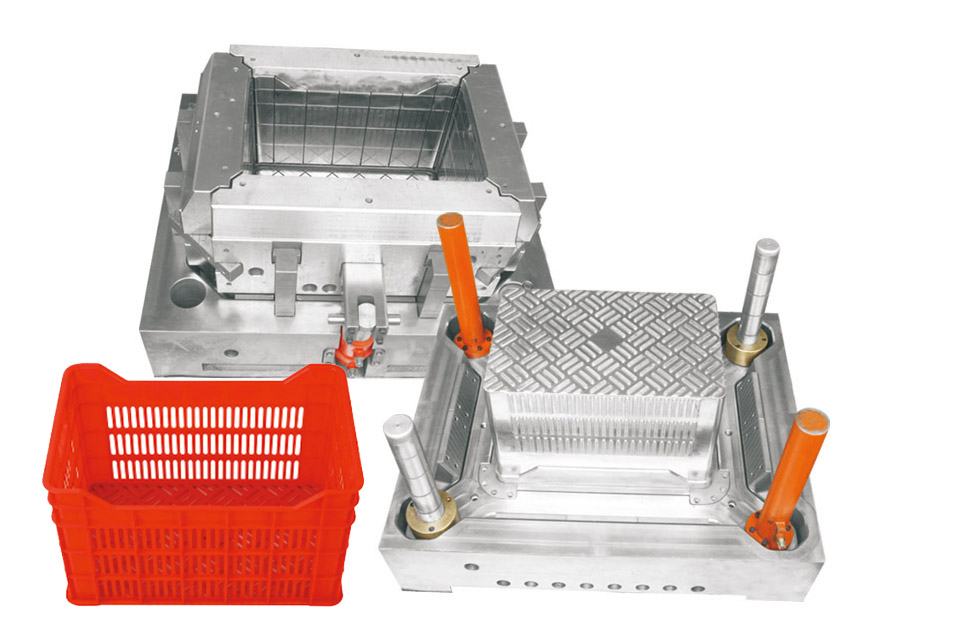

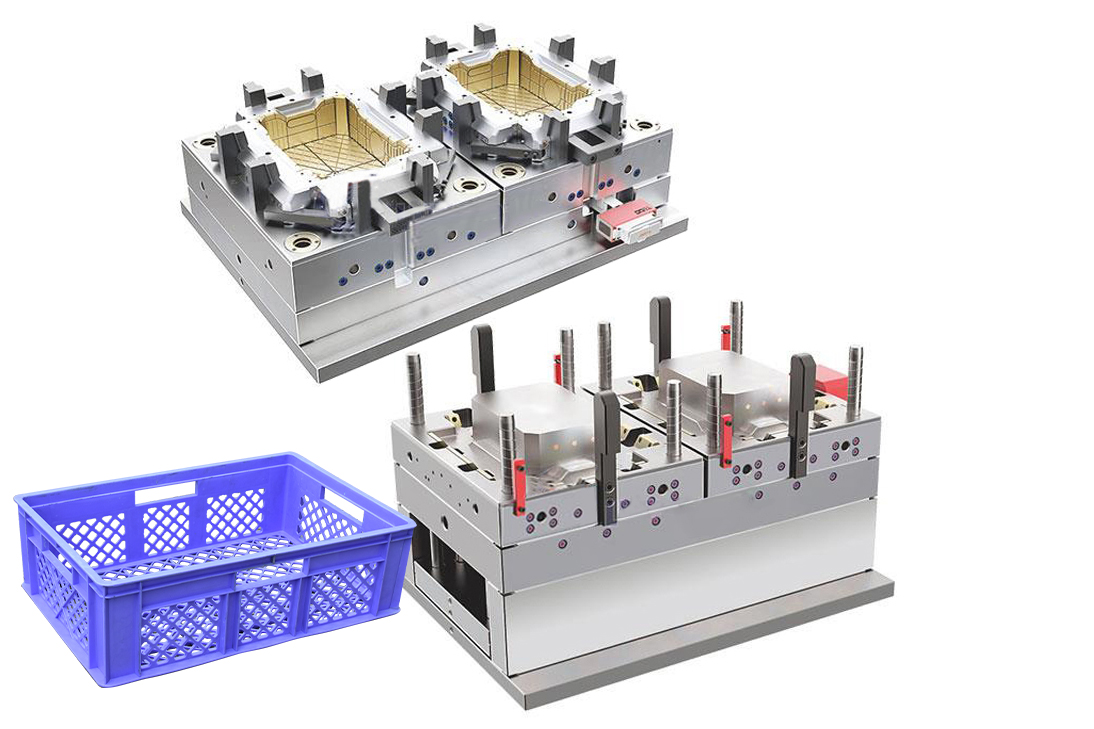

Turnover box mould

We manufacture a large range of crate plastic injection molds for a variety of applications. It has very mature plastic turnover box mold manufacturing technology. The main core steel is usually beryllium bronze plus DIN 1.2311 steel.

Bochao Mold provides customers with nearly 80 plastic turnover box molds every year. Bochao has a very strict control system to ensure the provision of the highest quality turnover box molds. At the same time, in order to shorten the production cycle of plastic turnover box molds, we also specialize in the production of standard molds. This can ensure the quality of plastic turnover box molds and save the production cycle of the molds. If you are interested in plastic turnover box molds, please contact us to get the best price for plastic turnover box mold solutions.

Compared with other types of turnover boxes, the structure of the beer box is more complex. In order to shorten the cooling time, the surface is made of beryllium copper structure, and a core pulling mechanism is used during molding. Since the beer box is an exterior part, the beer box plastic parts are required to be molded. The deformation is small, making it easy to assemble the mold. There should be no gate or ejection marks on the surface of the plastic part.

The four walls of the beer box mold need to be core-pulled and adopt a four-sided bark structure. During production, sometimes the bark is wedged too tightly, so that the beer box product remains in the unparted bark and is difficult to come out. To this end, a The retractor hook solves this problem. It moves outward as the retractor hook moves and automatically separates from the retractor hook.

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould

-

- Turnover box mould

Plastic turnover box Mould